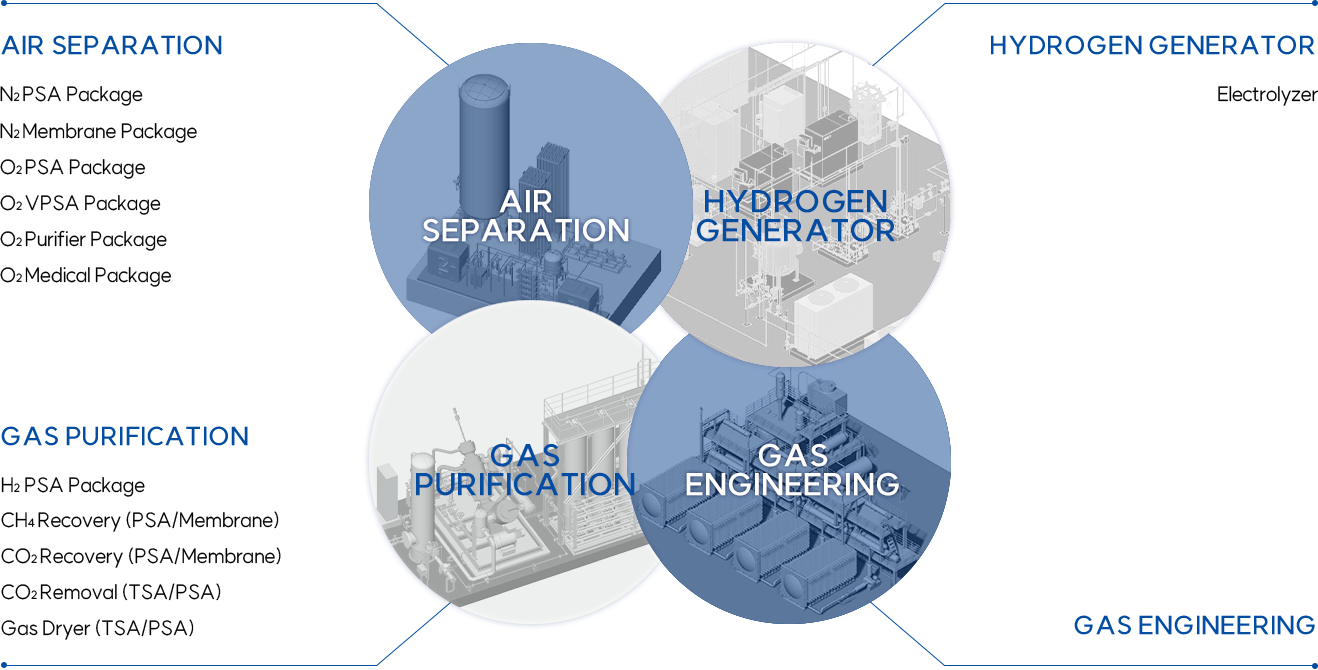

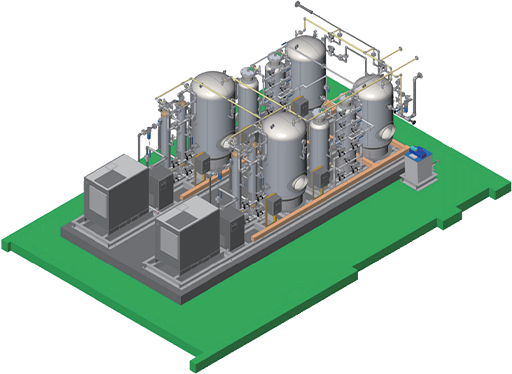

ASPE Inc. is a specialized gas engineering company providing the complete solution from design, manufacturing to commissioning & start-up service based on leading edge air separation & gas purification technologies.

Since its founding in the year of 2000 ASPE Inc. aims to grow into a global company specializing in gas separation, gas purification & gas engineering by concentrating all our capabilities on relentless internal innovation and technology development until now.

Despite any changes in the economic environment ASPE Inc. with its world's best technology will be a sustainable, trustworthy & reputable company by actively developing and nurturing new driving forces through global marketing.

With all of staffs at ASPE Inc. I also do pledge that we will develop into a company with the best value.

We look forward to having your continuing support and interest in the future.

Thank you.

Heung Seob, Lee

Chief Executive Officer